Understanding Floor Tiles Manufacturing

Overview of Floor Tiles – Types and applications

Floor tiles manufacturing is a meticulous craft, blending tradition with innovation to produce durable and aesthetically pleasing surfaces. It’s fascinating how a simple slab can transform a space, reflecting both style and functionality. According to industry data, the global market for floor tiles continues to grow steadily, driven by urbanisation and the demand for sustainable building materials. This underscores the importance of understanding the nuances within the manufacturing process.

Different types of floor tiles serve diverse applications, from high-traffic commercial areas to cosy residential interiors. Common options include ceramic, porcelain, and stone tiles, each offering unique benefits and challenges. For instance, porcelain tiles are renowned for their resilience and low porosity, making them ideal for outdoor spaces. Meanwhile, ceramic tiles provide versatility at a lower cost. The choice of material directly influences the manufacturing techniques used, impacting factors like durability, finish, and environmental footprint.

In essence, the art of floor tiles manufacturing is about balancing aesthetics with practicality. Whether creating glazed finishes or textured surfaces, manufacturers must consider the end-use environment and customer expectations. This careful process ensures that every tile not only meets industry standards but also elevates the spaces they adorn.

History and Evolution – From traditional to modern techniques

The story of floor tiles manufacturing is etched in shadows and light, a centuries-old craft that evolved through whispers of innovation and tradition. In ancient times, artisans relied on primitive methods, shaping clay and stone with reverence for nature’s raw materials. As centuries unfurled, the advent of glazed ceramics and intricate mosaics marked a renaissance—each tile whispering tales of craftsmanship rooted in history.

Modern techniques in floor tiles manufacturing have transcended these humble beginnings, embracing automation and scientific precision. Today, high-temperature kilns and advanced glazing processes enable the creation of resilient, aesthetically complex tiles that withstand the relentless march of time. The evolution is nothing short of remarkable, driven by a desire to blend beauty with endurance.

- Traditional handcrafting methods

- Introduction of mechanised production lines

- Innovations like digital printing for detailed designs

As the darkened corridors of history give way to sleek, modern factories, the essence remains unchanged: a relentless pursuit of quality and innovation in floor tiles manufacturing. This transformation, driven by technological advances, breathes new life into an age-old art—each tile a testament to the timeless dance between tradition and modernity.

Importance in Construction – Role in interior and exterior design

Floor tiles manufacturing plays a pivotal role in shaping both interior and exterior design. These durable and versatile materials not only define the aesthetic appeal of a space but also contribute to its functionality. In commercial and residential settings alike, expertly crafted tiles add value and character. The importance of high-quality manufacturing processes directly impacts the longevity and visual integrity of the finished product.

In modern construction, the choice of floor tiles can influence interior ambiance and exterior durability. From sleek porcelain to rustic terracotta, each type of tile serves a specific purpose. The manufacturing process ensures that materials are consistently produced to meet strict standards, offering resistance to wear, moisture, and temperature fluctuations. This reliability is essential, especially in high-traffic areas.

Understanding the importance of floor tiles manufacturing means recognising its influence on design versatility and structural safety. Whether creating a contemporary look or restoring historical charm, the manufacturing techniques used determine the options available. It’s no exaggeration to say that well-executed manufacturing is the backbone of successful design projects. After all, each tile embodies a careful balance of craftsmanship and technological innovation—delivering beauty that endures.

Raw Materials Used in Floor Tiles Production

Ceramic and Porcelain Clays – Selection and preparation

When it comes to the intricate art of floor tiles manufacturing, selecting the right raw materials is akin to choosing the perfect ingredients for a gourmet dish—only here, the stakes are higher, and the results last for decades. At the heart of this process lie ceramic and porcelain clays, the unsung heroes of durable, stunning tiles. These clays are carefully sourced from deposits that boast the ideal balance of silica, alumina, and fluxes, ensuring the final product isn’t just pretty but resilient enough to withstand the relentless march of foot traffic and the whims of weather.

Preparation is crucial—clays are meticulously cleaned, refined, and blended to achieve the desired consistency. This stage transforms raw earth into a malleable, workable material that can be shaped into tiles with uniform precision. During the manufacturing process, the selection of raw materials impacts everything from the tile’s water absorption to its resistance to cracking. For example, high-quality porcelain clays provide a dense, low-porosity finish, making them perfect for outdoor or high-moisture environments. The foundation of successful floor tiles manufacturing lies in understanding that the raw materials aren’t just ingredients—they are the blueprint for longevity and aesthetic appeal.

Glazing Materials – Types and their functions

In the shadowed corridors of floor tiles manufacturing, the raw materials serve as the silent architects of durability and beauty. Among these, glazing materials are pivotal, cloaking the tiles in a shimmering armour that resists the corrosive touch of time and weather. These substances are more than mere coatings; they are the guardians of colour, texture, and resilience.

Types of glazing materials vary, each wielded with deliberate precision to achieve specific aesthetic and protective qualities. From transparent glazes that reveal the intricate patterns beneath to opaque, matte finishes that lend a mysterious allure, the choice influences not just appearance but the tile’s very essence. The functions of these materials extend beyond decoration—they act as moisture barriers, preventing water absorption and crack propagation during the rigorous process of floor tiles manufacturing.

In this dark dance of creation, the selection of appropriate glazing materials is a meticulous ritual. It involves balancing chemical compositions to ensure adhesion, durability, and visual appeal. The right glaze transforms a simple slab of clay into a piece of art that endures the harshest environments, embodying resilience and elegance in every inch. Truly, in the realm of floor tiles manufacturing, the alchemy of glazing is what elevates raw earth into timeless masterpieces.

Additives and Pigments – Coloration and durability enhancements

In the vibrant world of floor tiles manufacturing, raw materials are the unsung heroes that turn a humble clay slab into a masterpiece of resilience and style. Among these, additives and pigments play a crucial role—think of them as the secret spices in a gourmet recipe, elevating the final product from bland to breathtaking. These compounds not only enhance the colour palette but also bolster the durability of the tiles, ensuring they withstand the chaos of modern life without losing their charm.

For colour enthusiasts and durability aficionados alike, pigments are the magic wands. They come in a kaleidoscope of shades, meticulously chosen to achieve specific visual effects and resist fading over time. Additives, on the other hand, serve as the silent guardians against water infiltration and crack formation—vital in the unpredictable realm of floor tiles manufacturing. To streamline production, many manufacturers rely on a strategic blend of these elements, often presented as:

- Metal oxides for rich, lasting colours

- Silica and alumina to improve strength

- Fluxes to enhance glaze adhesion

Ultimately, the alchemy of raw materials, additives, and pigments transforms simple earth into durable, eye-catching floor tiles that hold up under the pressures of daily life—proof that even in a world of concrete and steel, a splash of colour and resilience can make all the difference.

Other Components – Reinforcements and fillers

In the sophisticated ballet of floor tiles manufacturing, the raw materials are the prima donnas that make the performance truly spectacular. Beyond the glamour of pigments and glazes, it’s the humble yet essential components—reinforcements and fillers—that provide the backbone of durability and structural integrity. These elements ensure that each tile not only dazzles with colour but also stands firm against the test of time and traffic.

Reinforcements such as fibres and mesh are subtly woven into the mix, acting as the silent guardians against cracking and warping. Meanwhile, fillers like quartz and limestone powder serve to optimise the composition, reducing porosity and enhancing surface smoothness. To streamline the manufacturing process, many industry leaders employ a strategic combination, including:

- Calcium carbonate for added strength

- Fibre reinforcements for crack resistance

- Silica fillers to improve surface finish

These ingredients, often overlooked, are the unsung heroes in floor tiles manufacturing—transforming raw earth into resilient, aesthetically pleasing slabs that can handle both the elegance of design and the rigours of everyday life. After all, what’s beauty without durability? Or strength without style?

Manufacturing Processes of Floor Tiles

Design and Moulding – Creating tile patterns and shapes

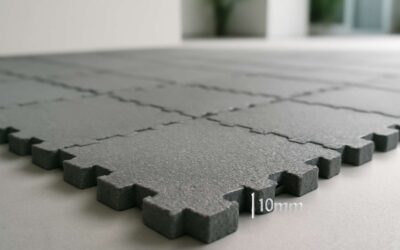

Creating intricate patterns and precise shapes is at the heart of floor tiles manufacturing. This process begins with designing the tile pattern, which can be as simple as a classic geometric motif or as elaborate as a bespoke mosaic. The design is then transferred onto moulds that define the tile’s shape and surface details. High-quality moulding ensures consistency across large batches, maintaining the integrity of the pattern and shape.

Manufacturers utilise advanced moulding techniques such as compression and injection moulding to produce durable, accurate tiles. These methods allow for complex designs to be stamped onto the tile surface, ensuring each piece is uniform. When shaping the tiles, special attention is paid to the edges and surface texture, which are critical for aesthetic appeal and ease of installation.

For added precision, some manufacturers employ digital moulding systems that can quickly adapt to new designs. This flexibility speeds up the floor tiles manufacturing process, making it possible to deliver customised options with tight tolerances. Ultimately, the creation of moulds and patterns is a vital step that defines the visual and structural quality of the finished floor tiles.

Pressing and Forming – Autoclave and hydraulic presses

In the shadowed realm of floor tiles manufacturing, the processes of pressing and forming play a pivotal role, shaping the very essence of durability and beauty. These steps transform the raw, earthen clay into the solid, unyielding surface that adorns our spaces. Central to this transformation are autoclave and hydraulic presses—machines that exert immense force to meld the components into a unified whole. The silent machinery presses the clay mixture with relentless precision, ensuring each tile bears the mark of perfection.

During pressing, the mixture is compacted under high pressure, which eliminates air pockets and enhances the tile’s structural integrity. This is followed by firing, where the tiles are subjected to extreme heat, creating a bond that is both resilient and enduring. The process is meticulous, often involving

- the application of automated control systems

- temperature regulation

- pressure adjustments

to guarantee consistency across large batches of floor tiles manufacturing.

Some manufacturers employ advanced digital moulding systems, enabling rapid adaptation to bespoke designs while maintaining tight tolerances. This seamless blend of tradition and innovation ensures the production of floor tiles that are not only visually striking but also built to withstand the relentless march of time. Truly, in the dark corridors of manufacturing, every press stroke echoes with the promise of enduring craftsmanship—an eternal testament to skilled artisans and relentless machinery alike.

Drying Techniques – Air drying and oven drying

In the intricate world of floor tiles manufacturing, ensuring optimal drying techniques is essential for producing durable and high-quality tiles. Two primary methods dominate the industry: air drying and oven drying. Each plays a vital role in the final stages of manufacturing, impacting the strength and finish of the tiles.

Air drying involves exposing the freshly pressed tiles to natural or controlled ambient air, allowing moisture to evaporate gradually. This method is energy-efficient and suitable for large batches, but it requires ample space and time. On the other hand, oven drying accelerates the process using specialised kilns or industrial dryers. The tiles are subjected to precise temperature control, which not only speeds up drying but also enhances uniformity across the batch.

Some manufacturers combine both techniques, starting with air drying to remove bulk moisture, followed by oven drying for final stabilisation. This hybrid approach optimises productivity without compromising quality. Whether employing air drying or oven drying, the goal remains the same: creating perfectly dried tiles ready for the next phase of floor tiles manufacturing. The choice of method influences the overall integrity and appearance of the finished product, making it a crucial consideration in the production process.

Firing Process – Kiln types and firing conditions

In the captivating realm of floor tiles manufacturing, the firing process is the unsung hero determining the durability and visual appeal of each tile. This stage involves subjecting the shaped clay or ceramic body to intense heat in specialised kilns—think of it as a fiery metamorphosis. Interestingly, kiln types can vary, with traditional tunnel kilns and modern roller hearth kilns leading the charge. Each offers distinct advantages: tunnel kilns provide consistent temperature control for large batches, while roller hearth kilns deliver rapid, uniform firing, perfect for high-volume production.

The firing conditions—temperature, duration, and atmosphere—are meticulously calibrated to optimise the final product. For instance, porcelain tiles require firing temperatures exceeding 1200°C to achieve their signature hardness and translucency. Whether using reduction or oxidation firing atmospheres, the goal remains the same: ensuring the tiles reach their peak strength and aesthetic quality. These crucial parameters influence the tile’s porosity, colour stability, and overall integrity—key factors in floor tiles manufacturing that cannot be overlooked. In essence, the firing process is where raw materials are transformed into the resilient, beautiful tiles that will soon grace your floors.

Glazing and Coating – Application methods and curing

In the intricate dance of floor tiles manufacturing, the glazing and coating stages are where artistry meets precision, elevating raw materials into stunning, durable surfaces. Applying glaze or specialised coatings not only enhances the aesthetic appeal but also significantly boosts the tile’s resistance to stains, scratches, and moisture. This critical step can be executed through various methods, each tailored to achieve specific visual and functional outcomes.

One of the most common application methods is spray glazing, where an automated system evenly coats the tile surface, ensuring consistency across high-volume production lines. Alternatively, dip coating involves immersing tiles into the glaze bath, creating a uniform layer that lends a tactile richness to the finished product. For intricate designs or specialised finishes, digital printing technologies allow for detailed patterns directly onto the glazed surface, offering limitless creative possibilities.

Post-application, the glazed tiles typically undergo a curing process in specialised ovens, where controlled heat ensures proper adhesion, vitrification, and durability of the coating. This curing phase is essential, as it locks in the colour and finish, making the tiles ready for subsequent manufacturing stages or final utilisation. The precise calibration of application and curing parameters is a testament to the craftsmanship embedded within floor tiles manufacturing, transforming basic clay bodies into resilient, visually captivating flooring solutions.

Finishing and Quality Control – Polishing, cutting, and inspections

In the intricate realm of floor tiles manufacturing, the journey from raw material to a polished masterpiece hinges on meticulous finishing and rigorous quality control. Each stage demands a delicate balance between craftsmanship and scientific precision — a dance that determines the longevity and aesthetic allure of the final product.

Polishing plays a pivotal role in revealing the tile’s true character, transforming a once matte surface into a mirror-like finish that accentuates colour depth and texture. This process, often carried out through advanced abrasive techniques or diamond grinding, ensures smoothness while enhancing resistance to wear. Cutting, on the other hand, is executed with precision machinery that shapes tiles to exact specifications, whether for intricate mosaics or standard flooring.

A comprehensive inspection follows, where trained technicians scrutinise every inch for cracks, colour inconsistencies, or surface imperfections. An unordered list of key quality checkpoints often includes:

- Visual surface assessment

- Dimensional accuracy verification

- Adhesion and durability testing

This rigorous quality control process safeguards the integrity of floor tiles manufacturing, ensuring only the finest pieces reach the end consumer. In this way, each tile embodies not just durability but an enduring beauty born from relentless pursuit of perfection. Because in the end, the true essence of floor tiles lies in their capacity to withstand time’s relentless march — a testament to craftsmanship that honours both material and human endeavour.

Types of Floor Tiles and Their Manufacturing Specifications

Ceramic Tiles – Manufacturing specifics and characteristics

In the realm of floor tiles manufacturing, ceramic tiles stand out as a true marvel of craftsmanship and innovation. These tiles, forged from a meticulous blend of clay, kaolin, and feldspar, undergo a transformative journey from raw material to stunning flooring element. Their manufacturing specifics demand precision—clays are carefully selected and prepared to ensure optimal plasticity, allowing for intricate moulding and pattern creation. The firing process, often conducted in electric or tunnel kilns, solidifies the ceramic structure, granting durability and resistance to wear.

What makes ceramic tiles truly captivating is their diverse range of characteristics. They can be glazed for a glossy finish or left unglazed for a matte, textured surface. The glazing materials used in the process are crucial—they not only enhance aesthetic appeal but also bolster resistance against stains and moisture. During the glazing phase, various additives and pigments are infused to produce vibrant colours and intricate designs, making each tile a unique piece of art. The manufacturing process’s finesse ensures that these tiles meet stringent quality standards, resulting in floors that are both beautiful and resilient.

Porcelain Tiles – Differences and production methods

Within the realm of floor tiles manufacturing, porcelain tiles have carved a niche as the epitome of durability and elegance. Their distinctive manufacturing specifications set them apart from traditional ceramic tiles, largely due to the rigorous production process involved. Unlike ceramic tiles, porcelain tiles are crafted from a finer, denser clay mixture combined with high-quality silica and feldspar, which undergoes a meticulous mixing and pressing process. This results in a compact, less porous tile with remarkable strength.

The production method for porcelain tiles often involves high-temperature firing in specialised kiln chambers, sometimes reaching 1,200°C or more. This firing process vitrifies the material, creating a non-porous surface that resists stains and moisture—ideal for both indoor and outdoor applications. To enhance aesthetics and functionality, manufacturers may incorporate digital printing techniques, allowing for intricate designs and colour variations that are baked into the tile during firing. This advanced approach to floor tiles manufacturing ensures each piece is not only visually stunning but also highly resilient.

Moreover, the manufacturing process can include several innovative steps, such as:

- Granulation of raw materials for uniformity

- High-pressure moulding to achieve consistent thickness

- Controlled cooling to prevent warping and defects

By adhering to these stringent specifications, floor tiles manufacturing of porcelain tiles results in products that excel in longevity and style, making them a top choice for discerning architects and homeowners alike. The evolving techniques in production continue to push the boundaries of what these tiles can achieve, blending artistry with engineering precision in every batch.

Natural Stone Tiles – Extraction and processing considerations

Natural stone tiles hold a timeless allure, their origins rooted deep within the earth’s ancient crust. When it comes to floor tiles manufacturing, extraction and processing of these stones demand meticulous care and craftsmanship. Each slab is carefully quarried, often from rugged mountains or expansive quarries, where the raw material is subjected to rigorous selection to ensure durability and aesthetic harmony.

The processing stage transforms raw stone into elegant, functional tiles through a series of precise steps. These include cutting, shaping, and surface treatment, which can accentuate the stone’s natural veins and colour variations. The manufacturing specifications for natural stone tiles often emphasise minimal alteration, preserving their organic beauty while ensuring consistency in size and thickness. This delicate balance between nature’s artistry and human ingenuity is what makes natural stone a coveted choice in floor tiles manufacturing.

In the realm of natural stone flooring, the following factors are paramount:

- Type of stone—marble, granite, limestone, or sandstone—each requiring bespoke processing techniques.

- Surface finishing—polished, honed, or textured—to enhance slip resistance and visual appeal.

- Sealing and treatment—applied post-manufacture to protect against stains and moisture ingress.

Ultimately, the natural stone tiles produced through meticulous floor tiles manufacturing are a testament to the enduring dialogue between earth and craftsmanship, creating surfaces that are as resilient as they are breathtaking.

Digital and Printed Tiles – Advanced printing techniques

When it comes to floor tiles manufacturing, the variety of options can be as diverse as the colours in a painter’s palette. Digital and printed tiles have revolutionised the industry, allowing for intricate designs and realistic imagery that elevate any space. Advanced printing techniques—think high-resolution inkjet technology—enable manufacturers to produce tiles with stunningly detailed visuals, from sprawling cityscapes to delicate floral patterns. This innovation not only broadens aesthetic possibilities but also ensures each tile is a miniature masterpiece.

In particular, digital printing in floor tiles manufacturing offers unparalleled flexibility. It affords the ability to personalise designs, incorporate customised logos, or mimic natural textures with astonishing realism. The process involves applying durable inks directly onto glazed surfaces, which are then cured under high heat to ensure longevity. This method makes printed tiles a favourite for both commercial and residential projects seeking a unique visual impact.

- Enhanced colour vibrancy

- High-resolution imagery

- Long-lasting detail preservation

Manufacturers also focus heavily on the precision of production specifications, ensuring each printed tile maintains consistency in size and surface quality. Whether employing traditional glazed ceramic techniques or cutting-edge digital printing, the goal remains the same: creating resilient, visually stunning surfaces that withstand the test of time and traffic. It’s this blend of technological innovation and craftsmanship that drives the evolution of floor tiles manufacturing into a truly artful science. And let’s face it—who doesn’t want their floors to tell a story as captivating as the design itself?

Quality Assurance and Standards in Floor Tiles Manufacturing

Testing Methods – Durability, slip-resistance, and water absorption

In the intricate realm of floor tiles manufacturing, ensuring unwavering quality is paramount. As the industry advances, rigorous testing methods have become the backbone of delivering durable and safe tiles. Durability tests, for instance, simulate years of foot traffic and environmental stress, uncovering potential weaknesses before they reach the consumer. Slip-resistance testing assesses the surface safety, crucial for preventing accidents in both residential and commercial spaces. Water absorption tests reveal how well tiles withstand moisture intrusion, a key factor in preventing cracking and degradation over time.

To uphold the highest standards, manufacturers employ a variety of testing techniques, often adhering to international standards such as ISO or ASTM. These include:

- Mechanical strength assessments to gauge breakage resistance

- Coefficient of friction evaluations for slip resistance

- Water absorption and porosity measurements for durability under moisture exposure

Through meticulous quality assurance processes, floor tiles manufacturing strives to deliver products that not only meet aesthetic expectations but also stand the test of time and environmental challenges. This relentless pursuit of excellence ensures each tile embodies safety, resilience, and longevity—cornerstones of premium flooring solutions.

Compliance Certifications – Industry standards and certifications

In the captivating world of floor tiles manufacturing, excellence is not merely an aspiration—it is a mandate etched into every stage of production. Rigorous adherence to international standards and certifications forms the foundation of trust, ensuring each tile delivered meets the highest benchmarks of quality and safety. Industry standards such as ISO and ASTM are the silent guardians, guiding manufacturers through meticulous testing protocols that uphold durability, safety, and environmental responsibility.

To reinforce this commitment, many manufacturers pursue certifications like CE marking or Green Building standards, which attest to compliance with global criteria. These certifications not only validate the manufacturing process but also enhance consumer confidence in the longevity and resilience of the tiles. For example, a certified tile must pass stringent water absorption tests, confirming its resistance to moisture-induced cracking, while its slip-resistance rating ensures safety in high-traffic areas.

In the realm of floor tiles manufacturing, quality assurance is an intricate dance of precision and passion. It is about more than aesthetics; it is about forging enduring solutions that withstand the test of time and environmental challenges. Such dedication transforms ordinary materials into extraordinary flooring options, making compliance with industry standards not just a requirement, but a promise of excellence.

Sustainability Practices – Eco-friendly materials and processes

In the intricate realm of floor tiles manufacturing, sustainability is no longer an optional add-on but an essential element that shapes the industry’s future. Eco-friendly materials and processes are transforming traditional production lines into conscientious operations that minimise environmental impact. Manufacturers are increasingly adopting sustainable practices such as using recycled raw materials, low-emission glazes, and energy-efficient kilns. These initiatives not only reduce carbon footprints but also cater to a discerning clientele seeking green building solutions.

Standards in sustainability are upheld through rigorous adherence to eco-certifications, which verify responsible sourcing and environmentally sound manufacturing. For instance, some manufacturers implement a closed-loop water recycling system during production, ensuring minimal water wastage. Such practices demonstrate a commitment to environmental stewardship—an increasingly vital aspect of floor tiles manufacturing. By integrating these eco-conscious techniques, manufacturers create resilient, long-lasting tiles that align with global sustainability goals and meet eco-building standards.

To ensure comprehensive sustainability, many companies follow an ordered approach:

- select eco-friendly raw materials,

- optimize energy consumption during firing,

- and implement waste reduction strategies throughout production.

This meticulous attention to detail guarantees that each tile not only embodies durability and aesthetic appeal but also upholds the highest eco-standards. As the industry progresses, transparency in sustainability practices becomes a hallmark of trusted floor tiles manufacturing, inspiring confidence in clients and setting new benchmarks for responsible production.

Emerging Trends and Innovations in Floor Tiles Manufacturing

Smart and Interactive Tiles – Embedded technology innovations

In the ever-evolving landscape of floor tiles manufacturing, innovation is no longer a mere option; it’s an imperative. The advent of smart and interactive tiles is revolutionising how we perceive functionality and aesthetics. Embedded technology in these tiles opens up a spectrum of possibilities—from responsive lighting to temperature control—transforming ordinary surfaces into dynamic elements of interior design.

Emerging trends in floor tiles manufacturing are driven by a desire to blend utility with elegance. Interactive tiles that respond to touch or environmental cues are gaining popularity, offering both convenience and a touch of futurism. For instance, certain tiles now incorporate embedded sensors that detect movement, making them ideal for energy-efficient lighting in commercial spaces.

Furthermore, the integration of augmented reality (AR) capabilities allows designers and homeowners to preview different tile patterns and textures in real-time before installation. This innovation not only enhances creative freedom but also reduces costly mistakes. With these advancements, the future of floor tiles manufacturing promises a seamless fusion of technology and artistry, elevating the very concept of flooring into a realm of personalised, high-tech expression.

Eco-Friendly Solutions – Recycled materials and energy-efficient methods

In the relentless march of progress, eco-friendly solutions in floor tiles manufacturing have gained momentum, reflecting a conscientious shift towards sustainability. Today’s industry champions recycled materials—think reclaimed ceramic shards and glass fragments—integrating them seamlessly into modern tile production. This approach not only reduces landfill waste but also lends a unique character to each piece, turning sustainability into an art form.

Energy-efficient methods further redefine the landscape of floor tiles manufacturing. Advanced kiln technologies, such as hybrid firing systems, cut down on energy consumption while maintaining impeccable quality. Manufacturers are increasingly adopting water-saving techniques during the production process, aligning their practices with global ecological imperatives. Such innovations ensure that the beauty of durable tiles goes hand-in-hand with environmental responsibility.

Emerging trends also include the utilisation of natural dyes and environmentally friendly glazes, creating tiles that are both striking and safe. These eco-conscious choices reflect a broader industry realisation: that sustainability and aesthetic appeal need not be mutually exclusive. As consumers become more discerning, the push for greener alternatives continues to influence the very fibre of floor tiles manufacturing—making it a craft where conscience and creativity walk hand in hand.

Design Trends – Patterns, textures, and decorative finishes

Emerging trends in floor tiles manufacturing are transforming surfaces from plain to punchy with innovative patterns, textures, and decorative finishes. Today’s designers are ditching the dull in favour of tiles that tell a story—think tactile textures that mimic natural materials or bold geometric patterns that command attention. The advent of digital printing technology allows for hyper-realistic designs, giving each tile a bespoke, high-end feel without the hefty price tag.

Textures are no longer limited to smooth or rough; they now span a spectrum that includes embossed motifs, matte finishes, and even 3D reliefs. These subtle variations add depth and character, elevating the aesthetic appeal of both interior and exterior spaces. Meanwhile, decorative finishes such as metallic glazes or iridescent sheens create a captivating visual dynamic, especially under the glow of ambient lighting.

In this creative landscape, versatility is key. Manufacturers are increasingly exploring floor tiles manufacturing techniques that merge traditional craftsmanship with cutting-edge technology, allowing for an eclectic mix of styles and finishes. From textured stone looks to colourful mosaics, the design possibilities are practically endless—making each tile a tiny masterpiece in its own right.

Automation and Digital Fabrication – Industry 4.0 integration

The future of floor tiles manufacturing is being reshaped by the relentless march of Industry 4.0 integration, bringing automation and digital fabrication to new heights. Advanced robotics and smart machinery now streamline production, reducing human error while elevating precision and efficiency. This technological leap allows manufacturers to produce intricate patterns and customised designs at an unprecedented scale, catering to the growing demand for unique, high-quality tiles.

One of the most exciting innovations is the utilisation of digital printing technology, which enables hyper-realistic designs to be printed directly onto tiles. This means that natural stone textures, complex geometric patterns, or even personalised motifs can be achieved with stunning detail, all within a fraction of the traditional timeframe. Such advancements are making bespoke floor tiles manufacturing more accessible and affordable than ever before.

Furthermore, automated quality control systems, equipped with machine learning algorithms, continuously monitor each tile for consistency and defects. This ensures that every piece leaving the factory meets rigorous standards, reducing waste and enhancing sustainability. As the industry evolves, manufacturers are adopting eco-friendly materials and energy-efficient processes, aligning innovation with environmental responsibility.

- Automated moulding and pressing for uniformity

- Digital printing for customised design options

- Robotic precision in glazing and finishing

- Real-time data analysis for process optimisation

In essence, the integration of Industry 4.0 in floor tiles manufacturing is not just about automation; it’s about creating a seamless, adaptable production landscape that champions creativity, quality, and sustainability. This revolution transforms raw materials into stunning, durable floor tiles that tell stories of innovation and craftsmanship, all while meeting the aesthetic and functional needs of modern spaces.

Distribution and Market Dynamics

Global Market Overview – Leading countries and export data

Floor tiles manufacturing isn’t just about pressing clay into pretty shapes; it’s a sophisticated dance of global market forces, technological innovation, and strategic distribution. The industry’s dynamic nature means that leading countries like China, India, and Spain continue to dominate export data, each bringing their unique flair — whether it’s cost-effective production or cutting-edge design techniques. In fact, China alone accounts for over 50% of worldwide floor tiles exports, a testament to its manufacturing prowess and extensive supply chain network.

Market dynamics are constantly shifting, influenced by consumer preferences for eco-friendly materials, technological advancements in digital printing, and the rise of smart tiles embedded with interactive features. Countries such as Brazil and Turkey have also carved out significant niches, especially in natural stone tiles and artisanal designs. As demand for high-quality, durable, and beautifully crafted tiles grows, so does the importance of strategic distribution channels.

- Efficient logistics networks

- Advanced warehousing solutions

- International trade agreements

all play vital roles in maintaining the flow of floor tiles from factories to retail outlets and construction sites across the globe.

Despite the complexities, the international floor tiles manufacturing industry remains robust, driven by burgeoning infrastructure projects and a surge in renovation activities worldwide. With the market becoming more fragmented and specialised, understanding the nuances of global export data and distribution strategies offers valuable insight into where the industry is headed — and how it’s staying resilient amidst economic fluctuations.

Supply Chain Considerations – Logistics, inventory, and retail

In the intricate world of floor tiles manufacturing, the supply chain’s complexity often goes unnoticed—yet it’s the backbone of the industry’s resilience. Efficient logistics, strategic inventory management, and seamless retail distribution form a delicate web that keeps the global market turning. As demand for innovative, eco-friendly tiles rises, companies invest heavily in sophisticated warehousing solutions and state-of-the-art transportation networks to ensure timely delivery. This is not just about moving products; it’s about orchestrating a symphony of moving parts that can adapt swiftly to market fluctuations.

Supply chain considerations extend beyond mere transportation. Modern floor tiles manufacturing relies on advanced data-driven inventory systems that anticipate demand spikes and optimise stock levels. The integration of digital platforms enables real-time tracking, reducing delays and minimising waste. Moreover, international trade agreements and customs protocols influence how swiftly tiles reach retail outlets and construction projects worldwide. To navigate this landscape, companies often implement

- automated warehousing

- just-in-time logistics

- multi-modal transportation options

—all vital in maintaining the flow of products from factories to end-users.

Understanding these market dynamics reveals an industry that’s not only about craftsmanship but also about strategic foresight. As the sector evolves, so does the importance of innovative distribution channels that can handle specialised tiles—whether natural stone or digitally printed designs—while ensuring that quality and aesthetics are preserved throughout the journey. With the right logistics infrastructure, floor tiles manufacturing continues to thrive amid global economic shifts, driven by a relentless pursuit of efficiency and excellence.

Challenges and Opportunities – Market growth and regulatory impacts

Distribution and market dynamics in the realm of floor tiles manufacturing are a fascinating dance of opportunity and challenge. As the industry surges forward, driven by a global appetite for innovative and sustainable designs, navigating market growth requires a keen understanding of regulatory impacts. Stringent standards across different regions shape how companies develop and distribute their products, ensuring quality while also pushing the boundaries of design.

The intricacies of market expansion often hinge on compliance with evolving regulations. For example, eco-friendly prerequisites demand that manufacturers incorporate recycled materials and energy-efficient processes, transforming traditional practices into sustainable pursuits. Meanwhile, emerging markets open new avenues for growth, yet they come with their own set of logistical and legal hurdles.

In this landscape, opportunities abound for those who can master the art of adaptive distribution. Digital platforms enable seamless connectivity, allowing real-time tracking of shipments and inventory, which is essential in a world that demands rapid response. As a result, companies in floor tiles manufacturing are leveraging advanced logistics solutions—such as multi-modal transportation and automated warehousing—to surmount challenges and seize new markets.

Market growth is not just about expanding boundaries but also about understanding the delicate balance of supply chain resilience and regulatory compliance. When these elements harmonise, the industry can flourish amid the shifting tides of global economic currents.

Conclusion

In the intricate dance of floor tiles manufacturing, every step reflects a deeper quest for perfection—a pursuit that mirrors our innate desire for stability and beauty in a transient world. Each tile, born from raw materials and crafted through meticulous processes, embodies more than just practicality; it becomes a testament to human ingenuity and resilience. The artistry behind floor tiles manufacturing is often overlooked, yet it holds the power to transform spaces into sanctuaries of comfort and style.

Ultimately, the true value of a floor tile lies not only in its durability but in its capacity to evoke emotion and meaning. As we walk across these surfaces, we engage in a silent dialogue with craftsmanship and tradition. It is this connection—between human hands, material, and purpose—that elevates floor tiles manufacturing from mere production to an act of creative expression. Recognising the moral and existential significance within this process enriches our appreciation for what often goes unseen beneath our feet.

0 Comments